Project Spotlight- TELUS Senior Remote

A Case Study- The TELUS Senior Remote Project

In 2016, Celadon partnered with TELUS to design and manufacture a custom remote control optimized for senior care environments. The result was an easy-to-use, hygienic, energy-efficient remote deployed across senior facilities throughout Canada

The Challenge

TELUS, one of Canada’s larger cable companies and telecommunications providers for residential, commercial, hospitality, and senior care customers, was using a standard remote control from another supplier. They realized that the senior care market has unique requirements and they would need a custom remote control with specific features to meet the needs of these customers. Some of these requirements included having large, easy to read buttons, a “smart” backlit keypad that would maximize battery life and being easy to clean or wipe down.

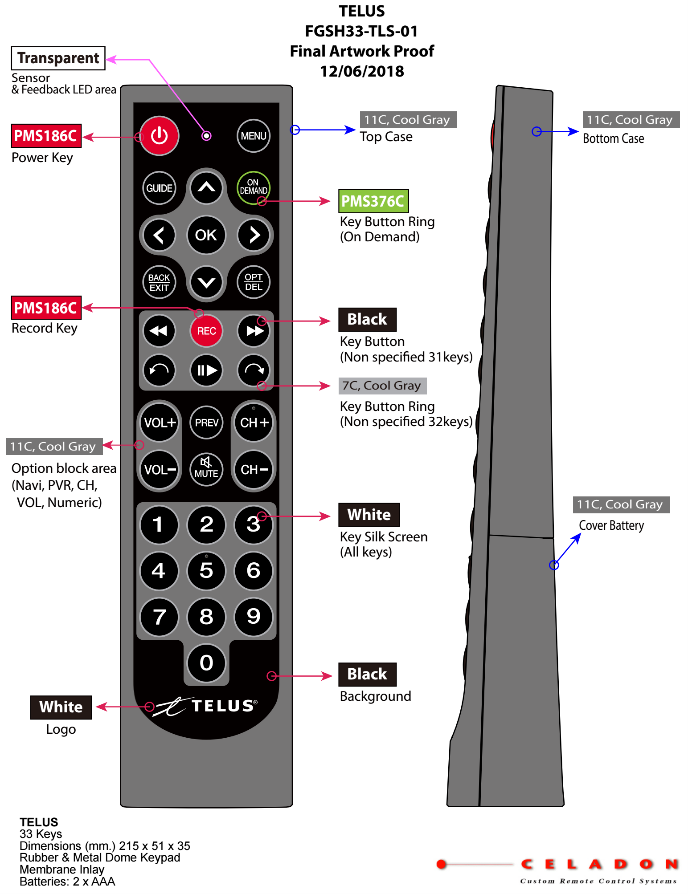

After several meetings to discuss the product requirements and general specifications, Celadon provided TELUS with a proposal for all the various design and development stages of the TELUS Seniors Remote Control including industrial design, mechanical design, electronic design, programming, artwork, 3D printed samples, tooling fabrication fees, first article samples, EMC testing and production setup fees. The proposal also included an estimate of the unit price, which was based upon the product specifications.

The Celadon Solution

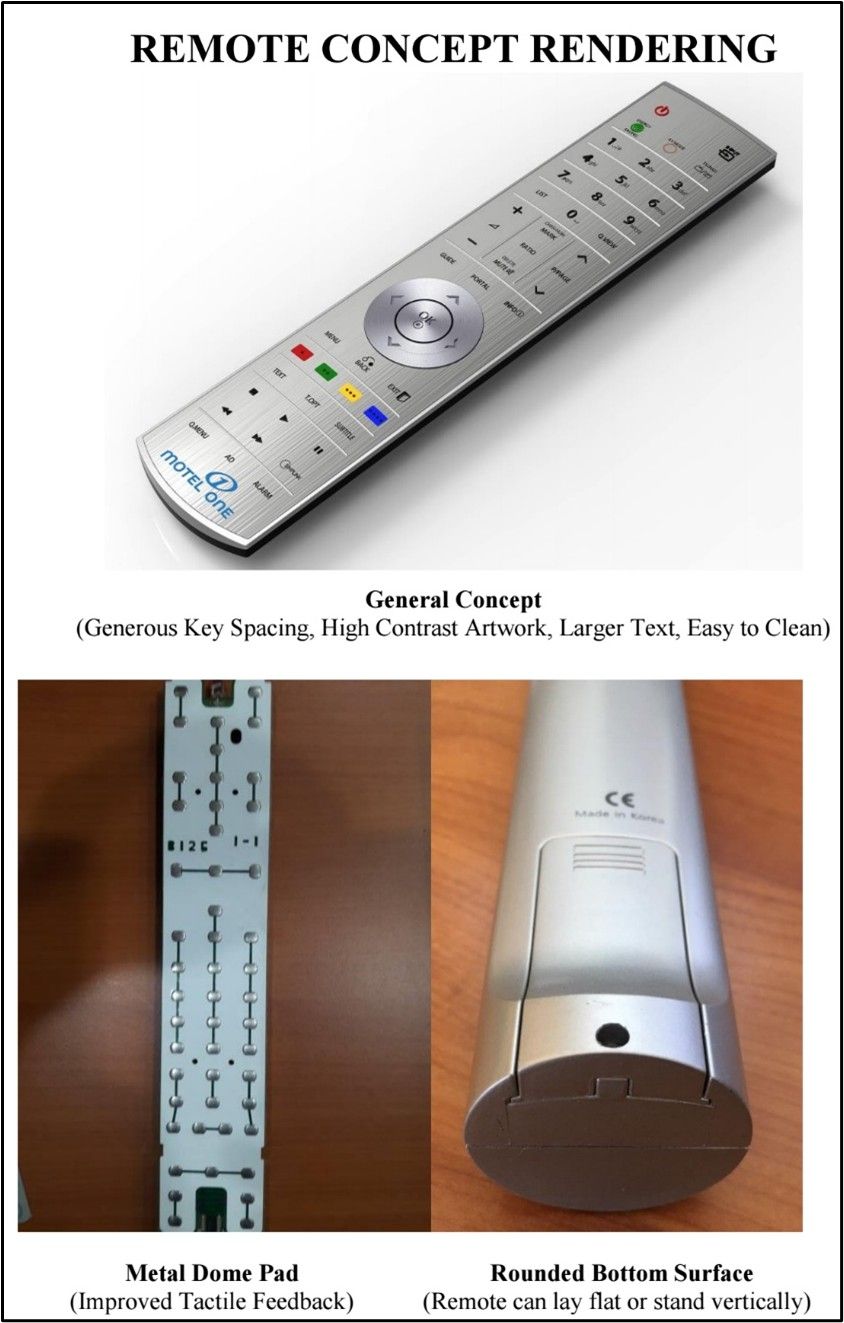

Celadon’s designers prepared concept renderings of the initial design for the project manager at TELUS to review. The concept included a unique feature which allowed the remote control to either lay flat on a surface or be able to stand vertically. A large membrane keypad mounted over a rubber keypad provided an easy to clean surface with strong tactile feedback for the user. Once the customer approved the concept design, the Celadon team was able to finish the industrial design of the remote and start the mechanical design for the various components of the remote.

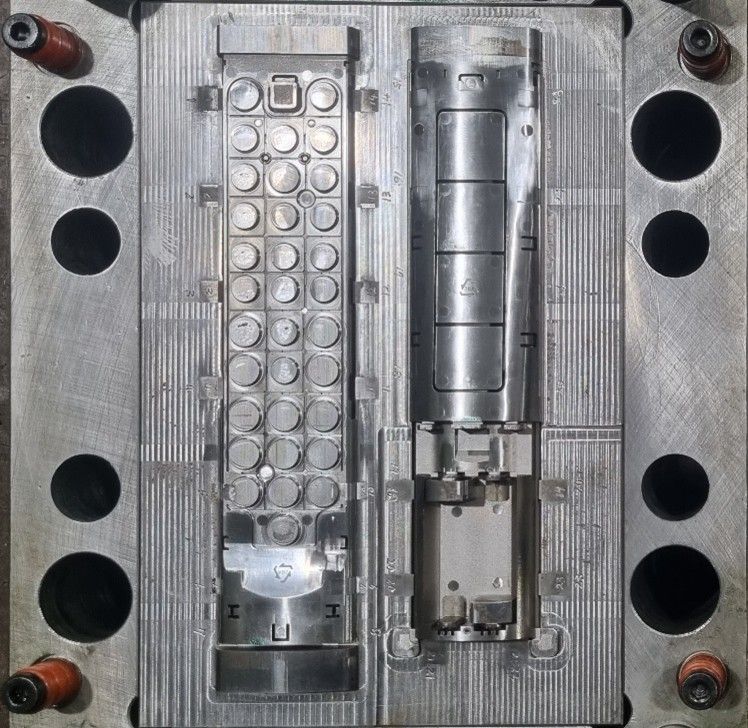

After the industrial design was reviewed and approved, Celadon had several 3D printed samples of the remote control prepared for the team at TELUS to review for final approval, prior to starting the tooling fabrication. TELUS was able to evaluate the 3D printed models for look and feel and approved the final design to start the tooling

Engineering and Testing

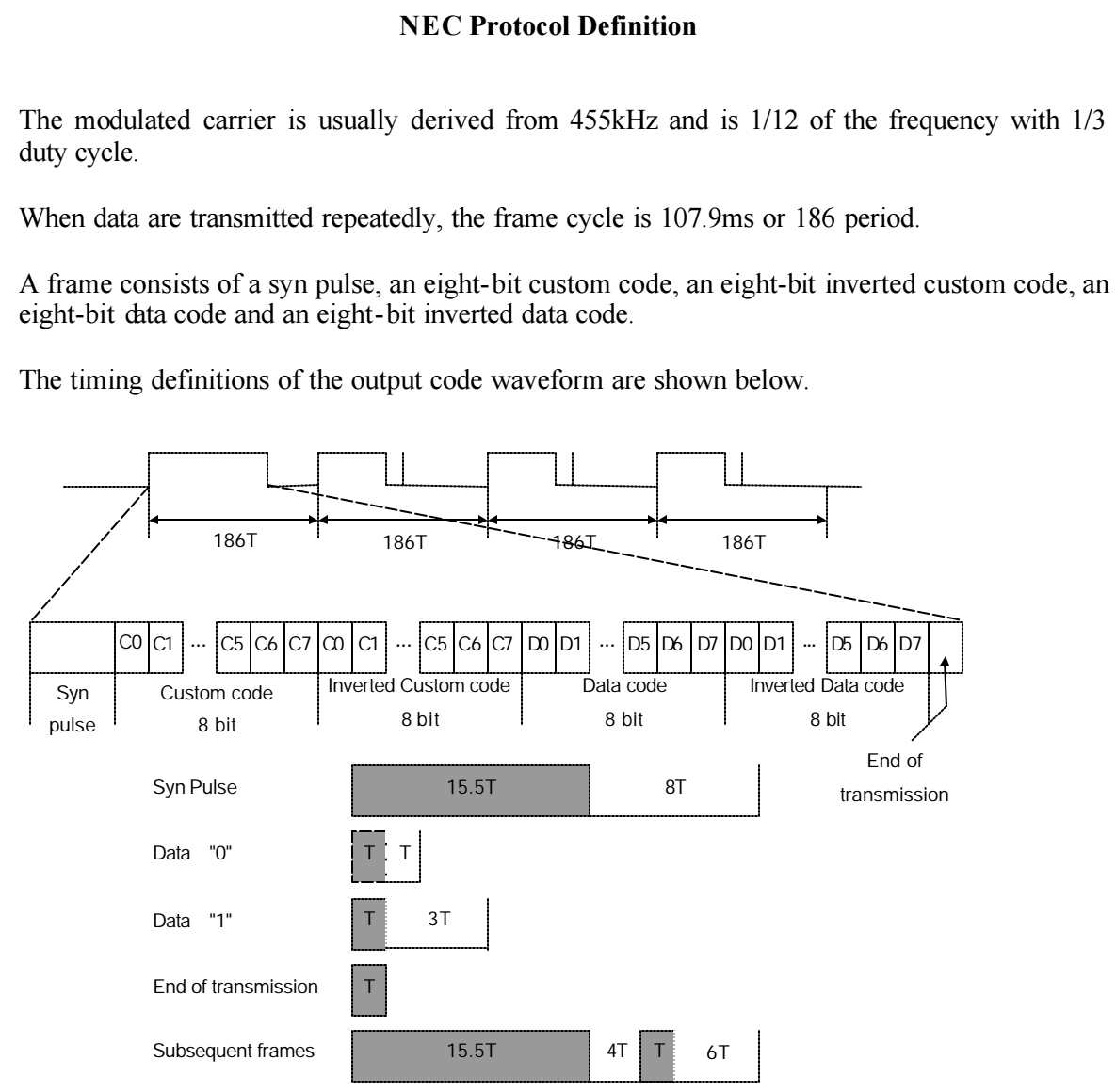

Tooling design and fabrication typically takes between 6-8 weeks before the initial plastic samples will be ready for inspection. During this time, the printed circuit board (PCB) was designed for the new model, and the microcontroller (MCU) was programmed to meet the customers’ requirements, which included a universal library of infrared codes for TV’s, codes for different TELUS cable boxes and incorporating easy setup procedures.

Celadon proposed a simple solution for the “smart” backlit keypad, where a combination of an ambient light sensor and tilt sensor was used to monitor the movement of the remote control when in a user’s hand and measuring the amount of light in a room to determine when to activate the backlighting of the keypad. The components required for this solution were very inexpensive and the battery life savings were considerable after the system was fine tuned for a typical room in a senior care facility.

First article samples using the new plastic components and the printed circuit boards were prepared by Celadon engineers for TELUS to test and approve for mass production. After the samples were approved, additional samples were prepared and submitted to our EMC test lab for all of the required standards for an infrared remote control to be marketed and sold in Canada. Test reports and certificates were provided to TELUS for their product records.

Manufacturing and Deployment

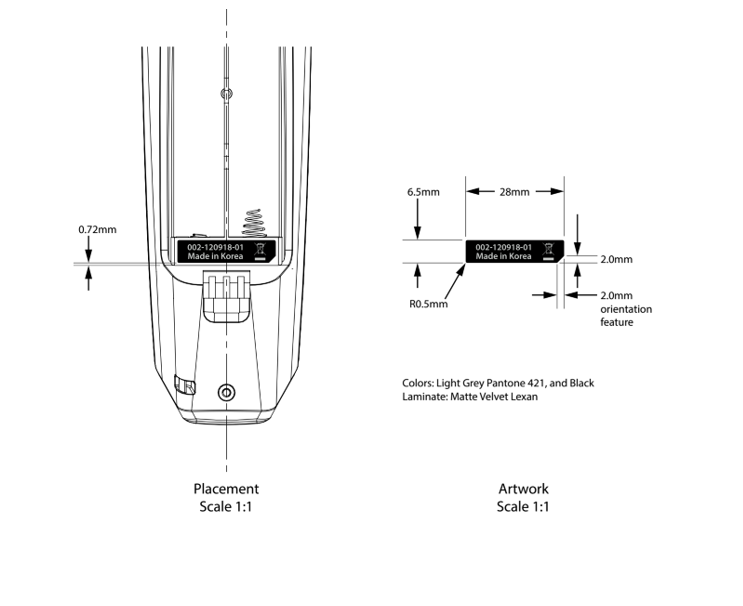

Mass production of the TELUS Seniors remote control took place at our ISO certified production facility in South Korea. The shipment was transported to Canada via ocean freight, and the logistics were coordinated by the team at Celadon. The TELUS remote control was delivered to TELUS and deployed to senior care facilities across several different Canadian provinces. The remotes proved a valuable tool for seniors by providing improved usability.

Count On Celadon for Your Project

Looking to develop a custom control solution for healthcare, hospitality, or enterprise environments? Celadon specializes in concept-to-production product development. Celadon provides free consultation services to discuss any new Infrared, Radio Frequency, or custom product development projects.

Please complete the Contact Us form on our website and a representative will contact you to discuss your project.

https://celadon.com/contact-us/

Mike Griswold • February 20, 2026